|

DEPARTMENT OF PHYSICS AND

ASTRONOMY

LINKS

|

Basics: Stimulated processes in hydrocarbon dissociaton

at model multilayer mirror surfaces

One of the most promising methods for next generation electronic device manufacturing

is extreme ultraviolet (EUV) lithography, which uses 13.5 nm wavelength radiation generated

from plasma-based sources. Buildup of reacted contamination layers during EUV exposure

leads to loss of reflectivity of the optics and results in unacceptable losses in lithographic

system throughput.

Capping layers of ruthenium films (~2 nm thick) are found to extend the lifetime of Mo/Si

multilayer mirrors (MLM) used in EUV lithography application. However, reflectivity of even

Ru-coated MLM degrade in time during exposure to EUV radiation. Ruthenium surface is chemically

reactive and is very effective as geterogeneous catalyst.

Our goal is to provide insights into the fundamental physical processes that affect the reflectivity

of Ru-coated Mo/Si MLM exposed to EUV radiation.

|

Recent Highlights:

Recent studies are related to the thermal and electron-induced interactions of model background

gases (toluene and benzene vapors) with the Ru surface. A low energy electron source (100 eV)

is used to simulate radiation excitations on the surface produced by EUV photons.

Heating of adsorbed hydrocarbons leads to a stepwise dehydrogenation and buildup a self-limited carbon

monolayer. Electron bombardment of the Ru surface in the presence of gas phase hydrocarbons results

in accumulation of carbon or carbonaceous species, which depends on gas pressure and the surface

temperature.

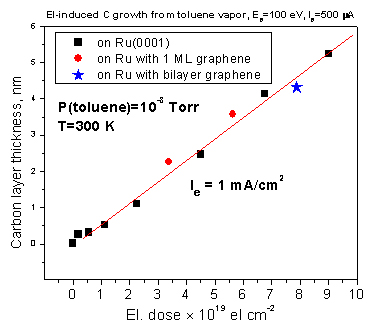

Graphene monolayer and bilayer formation on Ru(0001) is examined as a possible way to reduce the

surface contamination rate. We found that in a case of high electron flux, when the adsorption of

hydrocarbons is rate-limiting parameter, the carbon rate is invariant to the surface morphology (Fig 1).

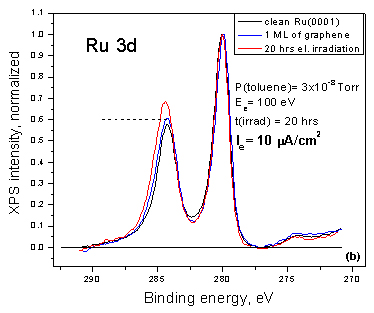

However, in a case of low irradiation density, when the electron flux is rate-limiting parameter,

graphene monolayer is shown to exhibit its protective properties by slowing down carbon accumulation

at initial stage (Fig. 2).

Figure 1. Carbon film thickness as a function of electron irradiation dose for the electron induced

reaction in the presence of toluene vapor at high electron current density.

Figure 2. Normalized Ru 3d XPS spectra illustrating the electron induced C accumulation on (a) carbon/Ru

surface and (b) graphene/Ru surface at low current density in the presence of toluene vapor.

The spectra are ordered from bottom to top as related to clean surface, precovered layer and resulting layer,

respectively. The starting point of toluene exposure is also marked with the dashed line.

|

Recent Publications

(back to top)

-

Interaction of benzene and toluene vapors with Ru(0001) surface: Relevance to MLM contamination

B.V. Yakshinskiy, Q. Shen, and R.A. Bartynski, Proc. SPIE, 7969, 796922 (2011)

-

Carbon film growth on model MLM cap layer: Interaction of selected hydrocarbon vapor with Ru(10-10) surface

B.V. Yakshinskiy and R.A. Bartynski, Proc. SPIE, 7636, 7636F (2010)

-

Electron-induced interaction of selected hydrocarbons with TiO2 surfaces: the relevance to extreme ultraviolet lithography

B.V. Yakshinskiy, S. Zalkind, R.A. Bartynski, and R. Caudillo, J. Phys.: Condens. Matter, 22, 084004 (2010)

-

Carbon film growth on model electron-irradiated MLM cap layer: Interaction of benzene and MMA vapor with TiO2 surface

B.V. Yakshinskiy, S. Zalkind, R.A. Bartynski, C. Caudillo, and T.E. Madey, Proceedings of SPIE - The International Society for Optical Engineering 7271(2009)

-

Measuring the EUV-induced contamination rates of TiO2-capped multilayer optics by anticipated production-environment hydrocarbons

S.B. Hill, N.S. Faradzhev, C.S. Tarrio, T.B. Lucatorto, R.A. Bartynski, B.V. Yakshinskiy, and T.E. Madey, Proceedings of SPIE - The International Society for Optical Engineering 7271(2009)

-

DIET processes on ruthenium surfaces related to extreme ultraviolet lithography (EUVL)

B.V. Yakshinskiy, R. Wasielewski, E. Loginova, M.N. Hedhili, and T.E. Madey, Surf. Sci., 602, 3220 (2008)

|

|